Over 698,000 strictly plumbing related posts

Plumbing education, information, advice, help and suggestions are provided by some of the most experienced plumbers who wish to "give back" to society. Since 1996 we have been the best online (strictly) PLUMBING advice site. If you have questions about plumbing, toilets, sinks, faucets, drains, sewers, water filters, venting, water heating, showers, pumps, and other strictly PLUMBING related issues then you've come to the right place. Please refrain from asking or discussing legal questions, or pricing, or where to purchase products, or any business issues, or for contractor referrals, or any other questions or issues not specifically related to plumbing. Keep all posts positive and absolutely no advertising. Our site is completely free, without ads or pop-ups and we don't tract you. We absolutely do not sell your personal information. We are made possible by:

|

|

Author:

sum (FL)

I needed to replace a section of the old 2" cast iron pipe with PVC, and I made the connection using a four band shielded no hub coupling.

The connection and piping was done several weeks ago and I was busy with other things but now I am ready to backfill so I decided to do a simple leak test. Yes I know the proper way is to stick a test ball at a downstream cleanout and have it back up to a certain height to get the necessary pressure and make sure it is leak proof for a fixed duration. However in this case I am just doing a simple test, sticking a garden hose down the cleanout about seven feet upstream of the connection and turned it on full blast for about 15 minutes.

I am getting NO LEAK - BONE DRY on the upstream end, where the PVC connects.

When I put my fingers under the downstream end, where the coupling connects to the cast iron, I feel a little moisture at the bottom. I wasn't sure if that's moisture from the surrounding soil, so I cleaned the coupling and underneath it, and even put a piece of 2X4 lumber under it to see if it catches any dripping. No dripping, but definitely a tiny bit of moisture under there.

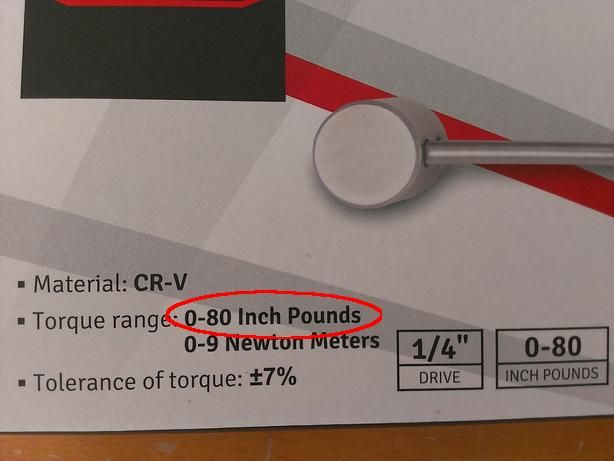

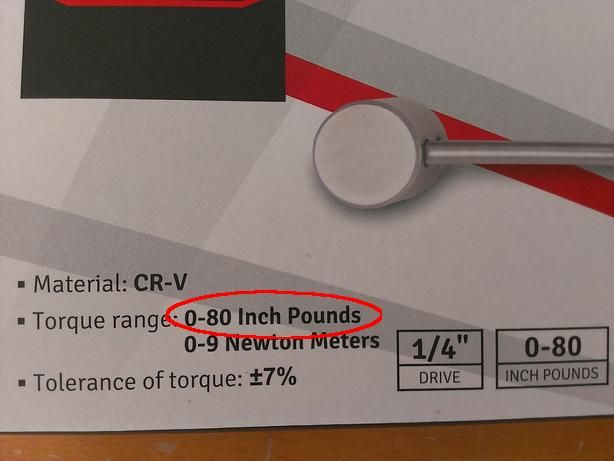

So here is what I did to make the connection. I made sure I sanded the cast iron all the way around to make sure there wasn't any protrusions or irregularities. I wiped the outside of the cast iron clean before I put the coupling on. I made sure the plastic sleeve is even seated right, and I tightened each band a little at a time, I used the manual torque wrench shown below and tightened it to 80 pound inches as specified.

The only thing I didn't do that I normally have done in the past was gluing a PVC no hub adapter.

Since there is a bit of moisture but no dripping for 15 minutes of flow, I manually tightened each of the four nuts another quarter turn. After running another test, I still feel the moisture under the pipe, but no dripping at all.

Any suggestions?

If I turn it any further I would be going above the 80#in torque. The cast iron is old and would I run the risk of collapsing the pipe if I over torqued it? The cross section of the CI pipe looks like there is 1/4" of thickness all around.

I wish I had applied some sort of grease or lubricant over the CI pipe before I slipped the coupling on but I didn't. If I had to do it now I have to take everything apart.

Edited 1 times.

|

|

Post Reply

|

|

|

Author:

North Carolina Plumber (NC)

That's the one I use for shielded couplings, hose clamps, etc.

|

|

Post Reply

|

|

|

Author:

sum (FL)

Vic I have this T-handle tool for 60#-in. I bought it previously to use with the Fernco PROFLEX shielded couplings with two 5/16" hex nuts.

This coupling is a "heavy duty" no hub coupling I bought at a local Ferguson and it has four 3/8" nuts and spec'ed to be tightened to 80#-in. That's why I used that other one above because I couldn't find one that does 80#-in with 3/8" hex nut head. I torqued it with the PRESA wrench to around 80#-in then tested it with a garden hose on full for 15-20 minutes. No driping but I felt moistute on the underside of the connection on the cast iron side.

Since then I have manually used a socket wrench to tighten it further with another quarter turn, twice. Just not sure if I may risk breaking or crushing the old cast iron pipe by torquing too much.

|

|

Post Reply

|

|

|

Author:

PlumberLoren (CA)

Sum, if you have 1/4" wall thickness..... IMHO, you will not have to worry about crushing the CI as long as it is not cracked.

|

|

Post Reply

|

|

|

Author:

hj (AZ)

When you plug the pipe and fill it with water, the lowest joints are subjected to about 5 psi pressure. When you "run water through the pipe" there is almost ZERO pressure so it is not really a good substitute for the test. IF there is a leak at that low pressure, there would have to be some MAJOR problem, other than just a "loose" joint.

|

|

Post Reply

|

|

|

Author:

sum (FL)

what could be the major problem?

I don't know if it's a leak. I put a piece of wood under the joint and turned the water on full with a garden hose. Not a drop of water. I even put a piece of tissue paper under and paper stayed dry. I ran the water for a good 20 minutes. It's a garden hose on full flow hooked to a 3/4" hose bib.

But if I put my fingers under the joint and felt it, I felt a tiny bit of moisture.

Is it possible for some sort of condensation forming on the underside of the cast iron pipe?

|

|

Post Reply

|

|

|

Author:

sum (FL)

I just thought of something.

When I cut the cast iron pipe I noticed the wall is unusually thick. In fact it's almost 1/2" thick. But of course this is not really the true thickness of the wall, but it's the buildup inside the pipe over the years.

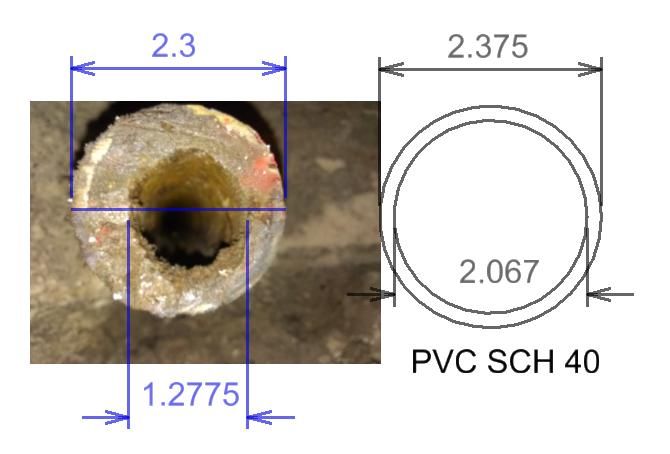

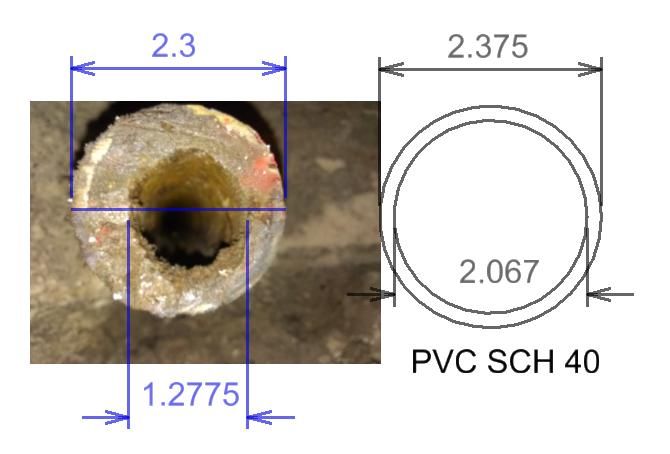

Here are the pictures of the cast iron pipe I connected to.

I looked up Charlotte's service weight pipe dimensions, and for a 2" pipe, the ID is 1.96" and OD 2.30".

I then looked up PVC SCH 40 pipe dimensions and for a 2" pipe, the ID is 2.067" and OD 2.375".

Now I took the picture and scaled it proportionally so that the ID of my CI pipe is 2.30", when I measured the ID I got 1.2775". The inside of the cast iron pipe is now 1.2775". See the picture below with my cast iron pipe dimensions, to it's right I also drew the 2" SCH 40 PVC pipe dimensions. See them side by side.

So when the flow transitions from the PVC to the cast iron, it's going from a 2.067" ID to a 1.2775" ID. This is a pretty significant "restriction".

I don't know if this is the reason for the really slow leak.

It seems this is also going to be a clog prone joint?

Edited 1 times.

|

|

Post Reply

|

|

|

Author:

North Carolina Plumber (NC)

That pipe needs to be water jetted.

|

|

Post Reply

|

|

|

Author:

sum (FL)

How would one jet this pipe?

Usually water jetting is from downstream cleanout and the jet shots backwards to "plow" the pipe right? So this is a 2" branch the jet will never get to it from a main line CO.

Unless one can go up to the roof and down the 2" PVC vent (the one I just put in to connect to it) and jets forward...

I can't tell from the pipe how much of it is original metal and how much of it is "buildup".

|

|

Post Reply

|

|

|

Author:

bernabeu (SC)

now you know why you getting these derelict properties cheap

==============================================

"Measure Twice & Cut Once" - Retired U.A. Local 1 & 638

|

|

Post Reply

|

|

|

Author:

sum (FL)

LOL, these are not cheap properties. They are old properties. For the most part real estate prices is driven by location and affected very little by anything else.

I actively seek out to buy older properties because they have stronger bones. The newest house I bought is from 1995 and it does not have less issues than a 1960 house like this one. In fact that newest house had half its PVC sewer line replaced by tunneling under the house for over 25' due to a dislocated 90 elbow in the middle of the house. I posted pictures of that episode and the work done by the "tunnel rat" company when that happened.

The reason I like older houses is because back then you have true craftmen working on them. That's why the interior walls have hand applied brown coat over gypsum over 1" thick instead of 1/2" sheetrock nowadays, the inside corners have wire meshes and not tape. The studs are all Dade County pine and three times heavier and not the soft 2x4 today. Electric runs in metal conduits that you can re-feed and repurpose if necessary,

and tells you how things are wired by looking at the conduit runs in the attic and provides EGC, instead of romex run a mok all over. Lower courses of exterior concrete blocks were filled with grout instead of hollowed, and always a strip of 3/4" wood over the sole plates for baseboard nailing, and type L copper pipes for supply lines instead of CPVC crap that seems to be in newer homes. So yes cast iron pipes can have issues but I would trade those other benefits in an older home in a heart beat.

|

|

Post Reply

|

Please note:

- Inappropriate messages or blatant advertising will be deleted. We cannot be held responsible for bad or inadequate advice.

- Plbg.com has no control over external content that may be linked to from messages posted here. Please follow external links with caution.

- Plbg.com is strictly for the exchange of plumbing related advice and NOT to ask about pricing/costs, nor where to find a product (try Google), nor how to operate or promote a business, nor for ethics (law) and the like questions.

- Plbg.com is also not a place to ask radiant heating (try HeatingHelp.com), electrical or even general construction type questions. We are exclusively for plumbing questions.

Search for plumbing parts on our sponsor's site:

Special thanks to our sponsor:

|