Over 698,000 strictly plumbing related posts

Plumbing education, information, advice, help and suggestions are provided by some of the most experienced plumbers who wish to "give back" to society. Since 1996 we have been the best online (strictly) PLUMBING advice site. If you have questions about plumbing, toilets, sinks, faucets, drains, sewers, water filters, venting, water heating, showers, pumps, and other strictly PLUMBING related issues then you've come to the right place. Please refrain from asking or discussing legal questions, or pricing, or where to purchase products, or any business issues, or for contractor referrals, or any other questions or issues not specifically related to plumbing. Keep all posts positive and absolutely no advertising. Our site is completely free, without ads or pop-ups and we don't tract you. We absolutely do not sell your personal information. We are made possible by:

|

|

Author:

sum (FL)

Some of you have commented on and expressed an interest in seeing the results of a science fair project my son is doing on determining if using primer makes a stronger PVC or CPVC joint.

Here is the initial thread with details and parameters:

[www.plbg.com]

Well, my son just finished all the tests this weekend and is now compiling the results. He made almost 500 PVC joints in the span of two weeks.

He tested five kinds of cement, regular clear, all purpose, rain n shine, blue lava and medium gray.

Primed and unprimed.

Joints were tested 2 hours after being made, 4 hours, 6 hours, and finally 24 hours.

Ten samples were made for each unique combination to eliminate random errors.

5x2x4x10=400 PVC joints were tested for compression.

Then the torsion tests were conducted on CPVC pipes and fittings. Only the all purpose cement were used, primed and unprimed, and tested at four time periods, ten samples each so 80 joints total.

Very interesting results.

Oh the guys at Home Depot all looked at me asking for 40 bags of 10 pack fittings but only 30' of pipes.

|

|

Post Reply

|

|

|

Author:

KCRoto (MO)

I wish I could have seen his face. Looking forward to the final report. =)

|

|

Post Reply

|

|

|

Author:

vic (CA)

".....500 PVC joints in the span of two weeks.

Very interesting results"

Come on sum .... we're dying to know the results.

|

|

Post Reply

|

|

|

Author:

BigReg1500 (CT)

SUM - I hope your son continues on with some sort of science or engineering study in college, and doesn't flake out like other kids today majoring in primitave cultures or gender studies with zero earning potential. Sounds like he is on his way!

|

|

Post Reply

|

|

|

Author:

sum (FL)

Yeah he wore gloves when making the joints, but the leather gloves were too clumsy, so he used disposable latex gloves which gives him much better control, BUT the spilled primer ate through latex gloves LOL.

|

|

Post Reply

|

|

|

Author:

sum (FL)

Vic soon he should have something preliminary.

It was actually more than 500. We had a bit of a false start in early October and had to throw a bunch of stuff out and rethink the process.

He finished testing but problem is he has to transcribe the results from his phone. You see we used a digital scale and torque thing and I held the camera to the readout while he applied the force. Each test was recorded as a video, so he needs to go back and pull off from the video the actual reading when each joint failed.

He needs to catch up on his sleep too.

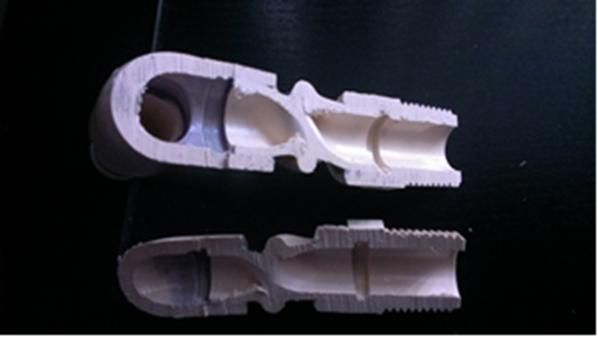

I didn't want him to operate the chop saw at his age so I did all the pipe cutting. Now I need to cut some of the joints in half - longitudinally - to see the difference of a cross section. Any idea on best way to get a clean cut that way? A table saw with the fence set at half pipe diameter and push it through?

|

|

Post Reply

|

|

|

Author:

sum (FL)

BufFet1500 thanks, I hope so. I think he enjoyed the process in working this out.

Had a few joints that "pushed out", I said its ok but he insisted discarding those as valid samples and had to redo them.

|

|

Post Reply

|

|

|

Author:

hj (AZ)

quote; primitave cultures or gender studies with zero earning potential. Sounds like he is on his way!

I don't know. This report may be just like those with ZERO pracical impact on anything or any one.Especially since he tested them to a standard which will never be encountered in the workplace.

|

|

Post Reply

|

|

|

Author:

hj (AZ)

The heat of the saw blade will "melt" the PVC and could distort you evaluation.

|

|

Post Reply

|

|

|

Author:

bernabeu (SC)

IF, repeat IF, the joint were to be PROPERLY 'solvent welded' it would become ONE PIECE and have the same tensile and shear strength as the plastic itself.

THEORETICALLY

Since the base plastic must be CLEAN for the solvent cement to work and the EASIEST / FASTEST way to clean it is using primer ..............................

ps. the taper in the fitting is what produces the 'clamping action' enabling the solvent cement to 'weld' the pieces together - so the actual 'weld' would be about 1/3 of the total depth, which is more than the wall thickness

THEORETICALLY

==============================================

"Measure Twice & Cut Once" - Retired U.A. Local 1 & 638

|

|

Post Reply

|

|

|

Author:

vic (CA)

"Any idea on best way to get a clean cut that way?"

I haven't a clue .... just hurry as I'm dying to know the results and who knows how long I can hold on

|

|

Post Reply

|

|

|

Author:

Paul48 (CT)

Sum.....I think it's a great project. I believe the results will give you the answers you're looking for. The differences created may be huge, or they may be small. Either way, it's valuable information. I'm looking forward to seeing it too.

Maybe the pvc manufacturer would like to contribute towards your sons college tuition? Nothing ventured, nothing gained.

Edited 1 times.

|

|

Post Reply

|

|

|

Author:

KCRoto (MO)

A table saw would be the fastest way, but you may have to notch out a piece of wood the same thickness as the outside of the fitting so that it can have something to keep it from flying apart. I think that you would get a better cut with a bandsaw if you have access, or even cutting slowly with a hacksaw. As Hj mentioned, melting is a factor, but if your blade is good and sharp on whatever you use it should cut before melting.

|

|

Post Reply

|

|

|

Author:

m & m (MD)

Sum, I think your son will do fine in life with initiative like that.

|

|

Post Reply

|

|

|

Author:

hj (AZ)

The melting will be caused by friction with the side of the spinning blade, not the process of cutting it.

|

|

Post Reply

|

|

|

Author:

sum (FL)

may be if I just whack it with a hammer to break it, even if the break is irregular I can still see the joint...unless the break happens to bust the joint loose, then that's no good.

|

|

Post Reply

|

|

|

Author:

BigReg1500 (CT)

When he's done with this project, can you have your son come up north and finish my gutter flusher project [www.plbg.com] for me? It's too cold now to mess around with water and metal pipe outside!

|

|

Post Reply

|

|

|

Author:

sum (FL)

BigReg1500, yes sure, just send me a plane ticket, the same one I sent Bernabeu  . .

|

|

Post Reply

|

|

|

Author:

sum (FL)

While he is busy compiling his results into a spreadsheets, let me start by posting some pics and fill in some background.

There are some preliminary discussions on the previous thread on PLBG I linked in the first post that went into some details as we planned the project.

But a quick summary this is my son's 10th grade science fair project. It was prompted by reading various DIY forums where even some professional plumbers claimed that they only used primer because it's required by code not because it made a better joint. Majority opinion is primer makes a better joint. So the thinking is let's do a test to validate this one way or another.

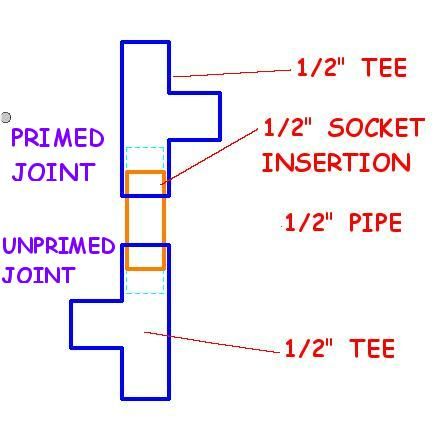

By a "better" joint, I think it has to mean a solvent weld joint made by primer + cement is stronger than one made without a primer. Strength in this context can be measured by it's ability to withstand tension, compression, torsion and water pressure.

There are some limitations, of course.

First, we couldn't test water pressure. We have no industrial equipment here just normal home use tools and what we can throw together. So we focused on the mechanical tests and skipped the water pressure test which would have given a good indication "is a primed joint less likely to leak?"

In order to test tension/compression, tension would have been a better test, but there is a safety consideration, so we decided on a simple setup to test compression.

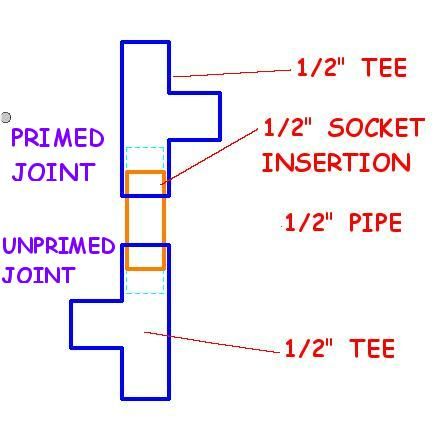

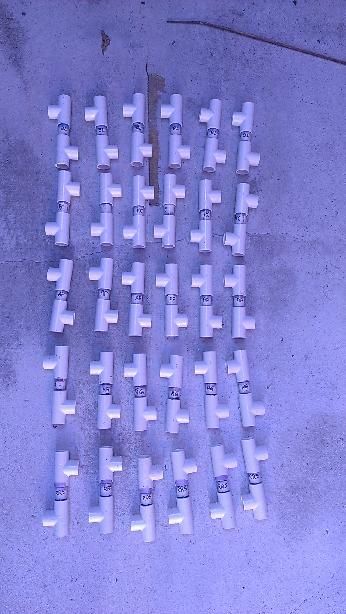

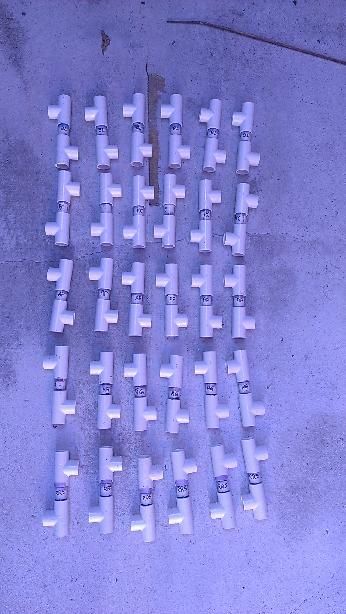

This is the sample we use. Two tees with a middle piece of pipe. The way it was done, each sample has two joints. One side is made with primer, the other side is made WITHOUT primer. We inserted the pipe 1/2" into the socket - NOT FULL DEPTH. I know we can debate that without full depth insertion, the joint is not "PROPER". However, EVERYTHING ELSE BEING EQUAL, the primed joint should still be stronger - THEORETICALLY, of course. The reason we did not go full depth, is so that during the compression test, there is room in the socket to allow the joint to fail in a controlled manner.

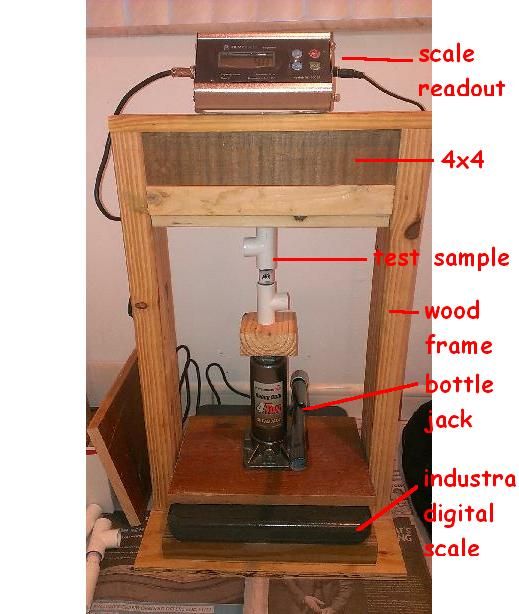

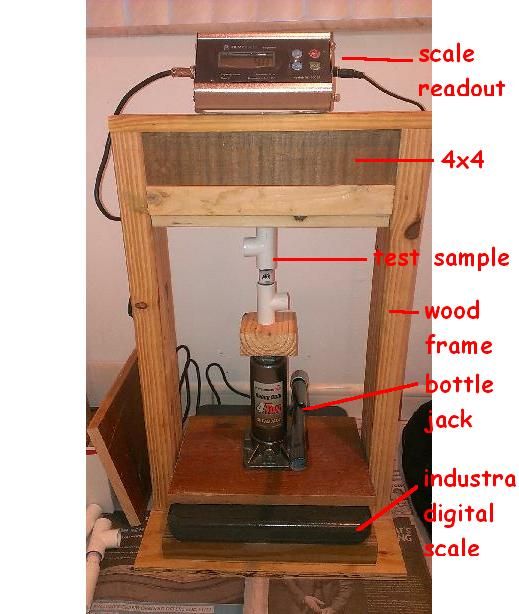

This sample is then subjected to compression. With this setup.

This is a wood frame I built for him using scrap 2x4s and 4x4s. Kind of similar to a pic KCRoto posted.

Onto the base is a industrial scale that would measure up to 500 pounds (which cost me $59.95 OUCH!!!), then a piece of wood to spread the load, then a bottle jack. The piece of the test sample is then inserted, as the bottle jack compresses the joints would fail and we record the force at the time of failure.

The way the sample is done, not only we can record the force to break the joints, but also which side (primed or unprimed with same cement) breaks first. He used five different types of cement. For each cement he made 40 such test samples, each with two joints. Ten tests on ten samples were done 2 hours after the joints were made, then 4 hours, 6 hours, and finally 24 hours according to manufacturer's specs when the joints should be fully cured.

So here is one such sample. "BL" means Blue Lava Cement was used, and you can see one side had primer the other didn't.

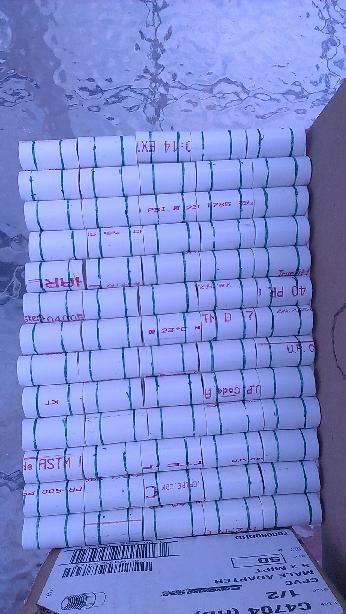

Here he lightly deburring the cut pipe pieces. I cut the pipes for him on a chop saw as I don't want him near that equipment yet especially when the cut piece is so short.

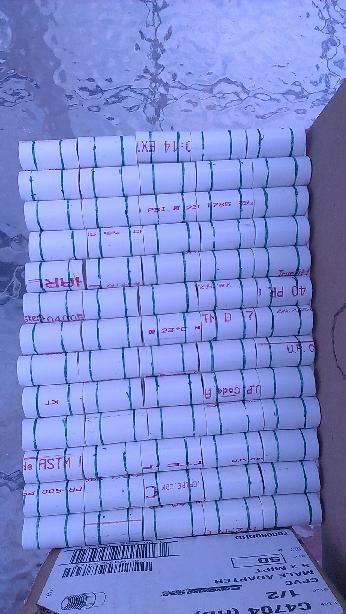

Here is one batch of pipes. He marked each side with a marker around to show 1/2" insert so when he made the joint he would be at the correct depth.

Here is him making the joints...I told him not to use disposable latex gloves LOL.

Here is one batch of joints.

Here is another batch. We did multiple batches over several weeks.

Edited 4 times.

|

|

Post Reply

|

|

|

Author:

sum (FL)

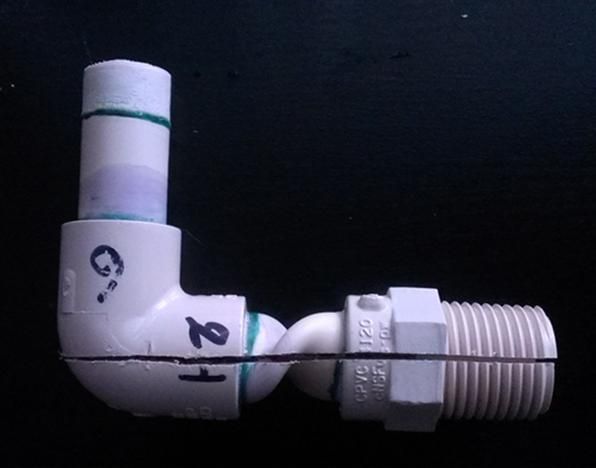

For the torsion test, the idea is essentially the same.

We choose to use CPVC pipes and fittings for this test, because of one single reason. The 1/2" CPVC male adapter has a hex shaped body, which allows us to use a hex shaped socket wrench to apply torsion.

I bought a digital torque adapter from Harbor Freight, for $30.

So we put together a sample. Each sample contains an 90 elbow in the middle. Then a short piece of pipe solvent welded to each end of the elbow. The other end a male adapter is attached. For each pipe, one end is primed, the other end is not. We then clamp it with a vise, turn the male adapter to break the joint and record which end (primed or unprimed) and the torque at which failure occurs.

Here is a picture of the setup.

Edited 1 times.

|

|

Post Reply

|

|

|

Author:

hj (AZ)

Use your test rig to push/force a wide "Bowie" knife through the plastic.Put the PVC on its side and go through it that way.

|

|

Post Reply

|

|

|

Author:

hj (AZ)

Why didn't you just put an adapter on each end of the piece of pipe, then chuck on end in the vise? Then twist until one end or the other failed?

|

|

Post Reply

|

|

|

Author:

hj (AZ)

IT will probably take him all winter because he will have to test all the possible mid point joints and then merge them will all the possible spray heads. HE has a future in the scientific world, as soon as he learns NOT to come up with a final solution which would put him out of work.

|

|

Post Reply

|

|

|

Author:

sum (FL)

because if we put the adapter on the vise, the contact with the vise will simply be the two small flat area of the hex part of the fitting. An elbow gives a larger surface area for the vise to clamp onto and it is less likely to "round out" and twist the entire fitting off the vise.

|

|

Post Reply

|

|

|

Author:

KCRoto (MO)

He could probably walk on to Mythbusters

|

|

Post Reply

|

|

|

Author:

sum (FL)

OK, here are some results.

Now, we know these tests weren't done in labs, not in a "CLEAN" environment, or in controlled humidity, temperature and atmospheric pressure, the process is manual, so take all that into account. However, I do think we tried enough samples to minimize random and statistical errors.

The results are a bit puzzling. So much so we stopped after our first batch of results, and had to regroup, trying to find out why the results didn't agree with what we expected.

We also know this is not going to change the perception of experienced plumbers just because of some 10th grade high school project, I am not sure I myself would change how I assemble a PVC joint because of this, but I am very curious and would like some answers to explain why we got these results.

So, here goes.

WHICH CEMENT IS THE STRONGEST?

Of the five cements we tried, Blue Lava, Rain or Shine, Medium Gray, All Purpose, Regular Clear, it seems Medium Gray gave the maximum strength resistant to the compression tests. This is a surprise, I was guessing Blue Lava or Rain or Shine would be on top.

DOES THE STRENGTH INCREASE AS TIME PASSES?

We tested the strength in compression at 2 hrs after assembly, 4 hrs, 6 hrs, and finally 24 hrs. It showed clearly the strength resistance increases as time passes. For example, one sample using Blue Lava cement failed at 2 hours at 200+ pounds, where after 24 hours it broke over 500 pounds, more than what the scale can measure. With the torsion tests, after two hours the joint twists apart easily. After 24 hours, half the sample would not twist apart, instead the pipe in between deformed. Oatey website on various cements documented a 15 minute to 2 hour cure time. It seems to achieve full cure it takes a much longer time.

ARE THE PRIMED JOINTS STRONGER THAN THE UNPRIMED JOINTS?

The answer is no. Of all the samples we tested, 70% of the primed joints failed BEFORE the unprimed joints. This number is actually misleading, because it's a TOTAL number of all the samples and all of the cements. Also if you look at our samples, we purposely put a primed joint on one end, an unprimed joint on the other and put it to the test, so we can get a HEAD TO HEAD compare, which one fails first? After two hours, all the primed joints failed first, except for 1 sample. After four hours, a couple more unprimed joints failed first. After 24 hours, it is more even, but still more than half of the primed joints failed first. This is true for both the compression and torsion tests. We are confused by this result.

Here are some thoughts as to why this happened.

Since the primer is supposed to pre-soften the PVC, it seems to suggest the assembled joints are softer than the ones where primer weren't used. So until it is fully cured, the primed joints are weaker/softer?

But even after 24 hours, we do not see an advantage (actually a slight disadvantage) offered by using primer, why? May be the primer's real purpose is to clean dirty PVC pipes and fittings? Like when you are assembling a repair joint in a dirty hole in the ground? But if the pipes and fittings are clean, it offers no advantages at all?

We tested the joint's mechanical strength - compression and torsion. We didn't test for hydrostatic pressure. We have no idea if the primer may be much better in the leak proofing department. We sort of assumed they would be consistent.

We also read that the ingredients that are in primer are now introduced into regular cement products to allow for a one step application. Blue Lava and Rain Or Shine do not require primers. Perhaps adding the primer ingredients into the actual cement makes a better joint then using primer then cement as a two step process?

We are still digesting the results. Any thoughts?

I am looking for a tech department at Oatey to see if we can begin a dialogue.

Edited 1 times.

|

|

Post Reply

|

|

|

Author:

vic (CA)

AWESOME sum. Thank you so very much.

"Since the primer is supposed to pre-soften the PVC, it seems to suggest the assembled joints are softer than the ones where primer weren't used. So until it is fully cured, the primed joints are weaker/softer? "

With your unexpected results (can't speak for others, for me they are unexpected) I would guess it has to with needing to be fully being cured however now I would need evidence (further test) results before affirming my ass-u-mptions that with time the primered joints would beat the none primered joints.

In my relatively short plumbing career (short "working" as apprentice, plumber, contractor) I never - ever had a PVC joint fail. I was taught to always use primer and if possible wait a day before turning on the pressures ..... now you've got me wondering if instead of primer (a pain in the rear due to hard to clean and hard to get the can to not leak once opened) I had always just cleaned each pipe/fitting very thorough producing as good if not better solvent welding results.

"But even after 24 hours, we do not see an advantage (actually a slight disadvantage) offered by using primer, why? May be the primer's real purpose is to clean dirty PVC pipes and fittings? Like when you are assembling a repair joint in a dirty hole in the ground? But if the pipes and fittings are clean, it offers no advantages at all?"

You're terrible   .... as in I don't like your results .... as in I don't like your results   .... you've taken my "facts" and turned them into "beliefs" .... actually you've gone even further than that as I'm now questioning my former "knowledge" and "experience" regarding my always insisting that one ought to use primer in ALL PVC solvent welding situations IF one desires to make "the best" possible PVC solvent weld. .... you've taken my "facts" and turned them into "beliefs" .... actually you've gone even further than that as I'm now questioning my former "knowledge" and "experience" regarding my always insisting that one ought to use primer in ALL PVC solvent welding situations IF one desires to make "the best" possible PVC solvent weld.

Wow ..... (I'm still blown away and glad I was sitting down when I read your son's results)

You're a great source of information, fun to read all that you write and I really appreciate it.

Again, thanks so much.

Vic

|

|

Post Reply

|

|

|

Author:

KCRoto (MO)

That is (for me) completely unexpected. I thought the cleaning agents in the primer would remove any residual traces of contaminants that would weaken an non-primed joint. I wonder if simply using cleaner and glue would produce the stronger joints then. I won't stop priming my joints for plumbing, but pvc can be used in many projects including building framework for portable structures and the like. Thanks for sharing Sum, I hope Oatey gets you in with the tech people there.

|

|

Post Reply

|

|

|

Author:

sum (FL)

vic and KCRoto,

Exactly, the results are completely unexpected. That's why after he did the first batch, I said let's retrace the steps and find out what went wrong. I couldn't find anything wrong...and granted, whether one use primer or not, you are not going to have a 300 pound man standing on the joint bouncing up and down, so either way, I think we are subjecting the joints to forces it is not designed for...but still, I expect the primed joints to be stronger in every which way at least when it's fully cured.

Here is a document we found on Oatey on cure time.

[www.oatey.com]

It shows the cure time needed for various diameters. That's what gave us the idea to test at different time intervals, and there is definitely a difference in strength as time goes from 2 to 4 to 6 to 24. At 24, we got a bunch of failure beyond 500 pound force, maximum the scale can handle. But even at 24 hours, still more unprimed joints held before breaking, compared to the primed joints. Whereas at 2 hours, most primed joints failed first. That was surprising.

I also had initially assumed, the most expensive cement would be the strongest. I think Rain Or Shine was most expensive, so that came as a surprise as well.

My son was the one who read the ingredients on both the cement and primer can and said there are a bunch of identical chemicals in them, is it possible modern day cement already contain the primer component and perform better without it?

I asked my son to compose a letter to Oatey and see if we can get some sort of a reply.

|

|

Post Reply

|

|

|

Author:

vic (CA)

"..is it possible modern day cement already contain the primer component and perform better without it?"

Good question  I wish I had a very old can to compare "modern" versus "the past." I wish I had a very old can to compare "modern" versus "the past."

Maybe many of us old timers in the last few (or many) years have been wasting time, money as well as have been giving out incorrect info.

I'd love to help be able to share your test results with the world.

With your and your son's permission when all has been completed I would love to be able to show your son's test results on a special unique info page at PlumbingSupply.com. We could show a picture of him and you (if you'd like), his school, dreams, etc and anything else as well as mention almost anything that he'd like to say or add.

No need to reply unless you think he'd like that.

My hat is off to both of you.

Vic

|

|

Post Reply

|

|

|

Author:

KCRoto (MO)

My guess would have been the clear glue. It is made for pvc specifically without any other additives.

|

|

Post Reply

|

|

|

Author:

sum (FL)

Vic, thanks for the offer! I spoke with my son and he is very excited about this, it makes such a big difference when he hears that someone actually care about his project and his findings.

It most likely won't change how pros assemble PVC joints, but I would like for him to follow up and find out why he got these unexpected results, its either primer is a non-factor in assembling clean joints in new construction, or there is something fundamentally wrong with his experiments and processes. Either way, he learns from this. Being able to show his results on plbg.com is such a validation to his putting in the work and selecting this project. When I talked to him in September, I suggested to him its better to pick out something practical and potentially useful, then those popular petri dish experiments that's been done to death.

His final report is due in less than two weeks, so he should have something more formal, with graphs, charts, conclusions to share as well.

Thanks again Vic!

Edited 1 times.

|

|

Post Reply

|

|

|

Author:

KCRoto (MO)

I can see it now!

Primer! The Truth, The Myth, The Experiment

|

|

Post Reply

|

|

|

Author:

KCRoto (MO)

Actually, it would be worthwhile to see if the primer dyes penetrated into the plastic or simply remained on the surface. If you could use a dissection microscope or something similar it may show it better. If the primer dye got down into the pipe, it could have caused a weakening/cutting in the polymer chains on a molecular level, making them something weaker that the original pvc compound. I wonder what the pvc manufacturer would say about this. It could be that the primed pvc is a entirely different polymer with different characteristics… things to ponder

|

|

Post Reply

|

|

|

Author:

sum (FL)

KCroto, I thought about that as well. My son were not able to get a hold of any microscope at school. They had some, but didn't allow him to use it because he's not taking a course that requires it. Schools these days have so many rules.

I then looked up Walmart, Best Buys etc...they sell a digital USB microscope, none at the stores but online you can buy one for less than $30.

Still no news from Oatey. This is frustrating...when we first contacted them they said sure let's talk then we provided some details, and since then nothing.

|

|

Post Reply

|

|

|

Author:

KCRoto (MO)

Did you just contact customer support, or did you get the tech department, or perhaps even a chemical engineer?

|

|

Post Reply

|

|

|

Author:

hj (AZ)

Do you really think they have time to discuss this? If they were interested in the subject, they would have to do their own "controlled" testing, not rely on an outside source. It may be like sending the plans for an 'improvement' to an existing item to the manufacturer. They will send it back and tell you that they are already working on something like it to avoid lawsuits over who thought of it first.

|

|

Post Reply

|

|

|

Author:

sum (FL)

KCRoto, there is no contact number on Oatey's web site except customer service, technical support and sales.

We sent an email CC to both customer service and technical support, thinking this will be forwarded to a more specialized division that would be interested in the results. We did get a reply from someone who says they would be like to see what was done, but when more information was sent, we got nothing. We will try another attempt.

|

|

Post Reply

|

|

|

Author:

sum (FL)

hj, that would be just fine if this prompted them to do some internal "controlled" testing like you said.

If they did their own tests, and there is no reason to believe they didn't, right? I mean if I were to sell a product the very first thing I would do is to test it and demonstrate why it's better, right?

If they show their tests and explain to us why the tests my son did were wrong and unreliable then we are OK with that, it's part of the learning process for my son.

|

|

Post Reply

|

|

|

Author:

sum (FL)

Here is one peculiar tid bit my son found. Check this out from Oatey's web site.

For the primer, the ingredients can be found here:

[www.oatey.com]

MSDS #2402E Part Numbers urple - 8766S, 8756S, 8746S, 8736S, 8724 Clear - 9366S, 9356S, 9346S, 9336S, 9324 urple - 8766S, 8756S, 8746S, 8736S, 8724 Clear - 9366S, 9356S, 9346S, 9336S, 9324

* * * Section 3-Composition / Information on Ingredients * * *

CAS# Component Percent

78-93-3 Methyl ethyl ketone 25-40

67-64-1 Acetone 25-40

108-94-1 Cyclohexanone 15-30

109-99-9 Tetrahydrofuran 15-30

If we pick just one cement, say the Regular Clear cement, the ingredients can be found here:

[www.oatey.com]

MSDS Number:1100C

Product Nos.:Clear-31015, 31016, 31470, 31471, 31472

Product Use:Cement for PVC Plastic Pipe

Section 3 COMPOSITION/INFORMATION ON INGREDIENTS

%wt/wt CAS NUMBER

Tetrahydrofuran 15-40% 109-99-9

Methyl Ethyl Ketone 10–30% 78-93-3

Acetone 10-20% 67-64-1

PVC Resin 10-20% 9002-86-2

Cyclohexanone 7-13% 108-94-1

If you compare the two ingredient lists and CAS numbers, they are essentially identical, except the cement contains PVC resin. All the ingredients are in comparable percentages, except Cyclohexanone has a lower percentage in the cement.

I am not sure how the different percentages make a difference...but I think perhaps there is an argument here to be made that the two are so similar that the one step application process actually create a better joint then the two step? Perhaps they have improved on the cement over the years to the point now it is actually superior?

Alternatively, one may ask, if ALL the ingredients of the primer is in the cement, then what is it that makes a better joint? Just the two step process? So what if I applied the cement twice?

|

|

Post Reply

|

|

|

Author:

KCRoto (MO)

The Pvc resin in the cement wouldn't allow you to press the fittings together properly if it dried, and more than one coat while it is still wet would just push out of the area where the bond occurs. Maybe the reduced cyclohexane in the glue only applications softens the pipe less and alters the chemical structure less, leaving you with an effect similar to bricks and mortar instead of a mortar only (the softened plastic) It all dries with time, but the softened area obviously doesn't get back to its original strength at all.

|

|

Post Reply

|

|

|

Author:

sum (FL)

"softened area obviously doesn't get back to its original strength at all."

That has to be true. If the solvent welding process would create a joint, as claimed, to be stronger than the original material, then we wouldn't have been able to break the joint apart this way. The jointed areas after assembly have twice the thickness, and the surrounding fitting and pipe are less thick, so theoretically they should never break apart there. So yes I think the pre-softened area by the primer never got back to their original state of strength.

Another thing that is clear, is that due to the primer's softening action, the joints are weaker while it cure. Our tests at 2, 4, 6 hours clearly showed the primed joints are weaker, but they seem to catch up to the unprimed joint as time passes and close to about the same at 24 hours. Oatey's cure time of 15 minutes, 1 hour or so at the web site seems to be incorrect...unless they meant cure "ENOUGH" to drain water but not to try to pull or twist them apart by mechanical means. The primed joints took much longer time to cure. I think the take away from this is you have a better shot at twisting apart to remake bad joint when primer is used. I remember one time I put in a 4" toilet elbow and after I glued in the riser was when I noticed it's leaning like 5 degrees.

|

|

Post Reply

|

|

|

Author:

bernabeu (SC)

sum,

you have convinced me on a personal level that my 'gut' re: plastic piping was correct

GARBAGE

the concept of 'solvent welding' does not work 'in situ' (actual practice)

it is, in fact, merely glued

==============================================

"Measure Twice & Cut Once" - Retired U.A. Local 1 & 638

|

|

Post Reply

|

Please note:

- Inappropriate messages or blatant advertising will be deleted. We cannot be held responsible for bad or inadequate advice.

- Plbg.com has no control over external content that may be linked to from messages posted here. Please follow external links with caution.

- Plbg.com is strictly for the exchange of plumbing related advice and NOT to ask about pricing/costs, nor where to find a product (try Google), nor how to operate or promote a business, nor for ethics (law) and the like questions.

- Plbg.com is also not a place to ask radiant heating (try HeatingHelp.com), electrical or even general construction type questions. We are exclusively for plumbing questions.

Search for plumbing parts on our sponsor's site:

Special thanks to our sponsor:

|

urple - 8766S, 8756S, 8746S, 8736S, 8724 Clear - 9366S, 9356S, 9346S, 9336S, 9324

urple - 8766S, 8756S, 8746S, 8736S, 8724 Clear - 9366S, 9356S, 9346S, 9336S, 9324