Over 698,000 strictly plumbing related posts

Plumbing education, information, advice, help and suggestions are provided by some of the most experienced plumbers who wish to "give back" to society. Since 1996 we have been the best online (strictly) PLUMBING advice site. If you have questions about plumbing, toilets, sinks, faucets, drains, sewers, water filters, venting, water heating, showers, pumps, and other strictly PLUMBING related issues then you've come to the right place. Please refrain from asking or discussing legal questions, or pricing, or where to purchase products, or any business issues, or for contractor referrals, or any other questions or issues not specifically related to plumbing. Keep all posts positive and absolutely no advertising. Our site is completely free, without ads or pop-ups and we don't tract you. We absolutely do not sell your personal information. We are made possible by:

|

|

Author:

sum (FL)

I have heard that the newer lead free ball valves are more prone to leaks, is this true? What are some things I should watch out for when soldering a new 3/4" LF ball valve to 3/4" type L copper? Do I put more heat on the copper pipe and less on the LF brass?

Should the ball valve be left closed, open or half open during the soldering?

I seem to remember asking about this before...I have seen some valves (I think globe valves) with a directional marker on the valve that dictates how they need to be installed. Is there a direction when installing a full port ball valve? Does it matter? Of course, this is assuming there is no flow direction marker on the actual valve body. A quick search on the internet made me more confused:

(1) ball valves should be installed such that the handle when opened points to the pressured side.

(2) ball valves should be installed such that the handle when opened points in the direction of flow - downstream.

(3) ball valves should be installed such that when opening you turn the handle counterclockwise and close in a clockwise direction.

which is it? or there is no universal convention?

Edited 1 times.

|

|

Post Reply

|

|

|

Author:

steve (CA)

Sum, add some heat to the pipe, but still concentrate on the fitting. I solder with valve open, unless I'm holding back water on one side. Handle up/down/left/right/upstream/downstream is up to you. You have zero choice on clock wise vs counterclockwise, that's built into the design of the valve. I have 4 different ball valve brands in my garage and they all close clockwise.

|

|

Post Reply

|

|

|

Author:

bernabeu (SC)

steve,

when running 'racked' pipe overhead horizontally it is 'good practice' (headroom issues not withstanding) to install handles so they 'pull down' to a vertical position to close valve

all your other advice is good (as usual)

==============================================

"Measure Twice & Cut Once" - Retired U.A. Local 1 & 638

|

|

Post Reply

|

|

|

Author:

packy (MA)

the reason there is a flow direction with globe valves is that the pressure should always comes from under the seat.

this way there is not constant pressure on the packing.

as for ball valves, each installation needs to make sense as for proper operation.

the handle can't hit a wall, a ceiling or another pipe.

|

|

Post Reply

|

|

|

Author:

hj (AZ)

1 & 2 it is a personal deicsion that I was NEVER concerned about. 3. That is determined by the manufacturer. YOU CANNOT change it, unless you remove the stop.

|

|

Post Reply

|

|

|

Author:

sum (FL)

steve, I worry about too much flame on the valve side because of those looks to be plastic seats that do the sealing. I wonder if too much heat may warp/melt them. I take the handle off when soldering but I can't remove the guts of the ball valve.

|

|

Post Reply

|

|

|

Author:

exapprentice30 (MA)

Lead free 95 tinning flux works great for lead free brass sweat fittings.

|

|

Post Reply

|

|

|

Author:

bernabeu (SC)

the 'plastic' seats are actually PTFE (teflon)

they are rated 550 degrees f.

==============================================

"Measure Twice & Cut Once" - Retired U.A. Local 1 & 638

|

|

Post Reply

|

|

|

Author:

sum (FL)

Another question.

How long does the flux on copper pipes and fittings stay viable if left unsoldered?

I was doing some copper pipe & fitting assembly yesterday afternoon. Involving a dozen copper fittings and three ball valves. I measured and cut each one, assembled it once and made sure they are correct. I then debited, sanded, cleaned and flux everything. Ready to solder. Then a phone call from a tenant about a leak on the floor, completely distracted me and I went there to investigate. Turned out it's the AC handler condensate line was pushed up and out of the condensate pump inlet by them squeezing brooms vacuum paper towels and other junk into the AC closet resulting in the condensate line discharging directly into the floor.

By the time I got home 3 hours later it's past dinner time and dark outside.

Can I start soldering it today or should I take it apart, reclean and reflux first?

|

|

Post Reply

|

|

|

Author:

srloren (CA)

Always disassemble ball valves prior to soldering and make sure there is no water in the system. The valve takes more heat due to its mass but move the flame back and forth to prevent over

heating. See:

[www.bing.com]

srloren

Edited 1 times.

|

|

Post Reply

|

|

|

Author:

packy (MA)

my friend from CA.

how in the world do you disassemble a sweat ball valve, solder it and reassemble when the are assembled from the end?

must be a left coast magic trick. hahaha

|

|

Post Reply

|

|

|

Author:

NoHub (MA)

Soldering...What's that?

|

|

Post Reply

|

|

|

Author:

packy (MA)

the problem is that when we are advising homeowners, we can't tell them to press the joints. none of them have the press tool.

[www.amazon.com]

|

|

Post Reply

|

|

|

Author:

bernabeu (SC)

nor, IMO, 'should' we tell them to make joints using "O" rings

IMO: hidden copper should be silver brazed, if done properly, the system becomes as good as 'home runs' but with COPPER as the piping

95-5 solder is 'near as' good

==============================================

"Measure Twice & Cut Once" - Retired U.A. Local 1 & 638

|

|

Post Reply

|

|

|

Author:

packy (MA)

bern, i too question the "O" ring technology.

when i worked at the navy yard (60's) we assembled very high pressure hydraulics (many thousands of pounds) with some kind of triple seal fittings. what i remember is a flare fitting that had an "O" ring on the nose of the male end.

|

|

Post Reply

|

|

|

Author:

sum (FL)

I soldered the three ball valves today. Tested them with a garden hose and no leak. I love sharkbite end caps for testing purposes.

|

|

Post Reply

|

|

|

Author:

NoHub (MA)

Who mentioned anything about a Press tool??

|

|

Post Reply

|

|

|

Author:

packy (MA)

i plead guilty to the charge.

pro-press is for professionals because of the expense involved with a tool needed.

besides the homeowners shop at big box stores or smaller hardware stores where propress fittings are not sold

|

|

Post Reply

|

|

|

Author:

srloren (CA)

Packy I will make a video to show you how it is done. My point was that overheating the valve should be a concern for sure. Especially for Newbys.

.

srloren

|

|

Post Reply

|

|

|

Author:

packy (MA)

i agree 100%. a brass valve body with a stainless steel ball BUT the ball sets in a teflon/plactic seat. distorting that seat is always a concern of mine. and even more of a concern with homeowners applying too much heat.

|

|

Post Reply

|

|

|

Author:

sum (FL)

I too would love to learn how to take apart the guts of a ball valve. I have always assumed that cannot be done.

|

|

Post Reply

|

|

|

Author:

bernabeu (SC)

@ sum ;

[www.bray.com]

'real' piping as per 'good/best practice'

NOT the typical consumer grade junk they sell today

$$$$$

==============================================

"Measure Twice & Cut Once" - Retired U.A. Local 1 & 638

|

|

Post Reply

|

|

|

Author:

packy (MA)

bern, i question separating 5 from 3 ??

|

|

Post Reply

|

|

|

Author:

bernabeu (SC)

packy,

'most' valves: the stem is male / the ball female - a simple groove with NO solid connection, the stem has a 'matching' protrusion (albeit not viewable in the parts diagram) - the ball (to a certain extent) 'floats' in order to make a tight seal under pressure against the seat(s)

this is really nit picking the finer points of steam/pipe-fitting

BUT

these 'fine points' (and many many many others) define a skilled journeyman

==============================================

"Measure Twice & Cut Once" - Retired U.A. Local 1 & 638

Edited 2 times.

|

|

Post Reply

|

|

|

Author:

sum (FL)

this is a threaded valve. we are talking about avoiding damages to full port ball valves with sweat connections while soldering, by removing the guts of the ball valve before soldering and putting them back afterwards. If it's threaded there is no need for disassembly other than for maintenance because there is no heat being applied to the body.

|

|

Post Reply

|

|

|

Author:

bernabeu (SC)

threaded - soldered - brazed - welded

the 'guts' will be the same

ALL the above will require some sort of 'union' connection for servicing - flanges come to mind

ps. how to assemble the soldered type - disassemble valve - remove seats - solder each 'piece' to a length (or appropriate scrap piece) of Cu Tube - reassemble to prevent 'contamination' - the rest should be obvious

oooops ..... actual pipefitting skills required

==============================================

"Measure Twice & Cut Once" - Retired U.A. Local 1 & 638

|

|

Post Reply

|

|

|

Author:

packy (MA)

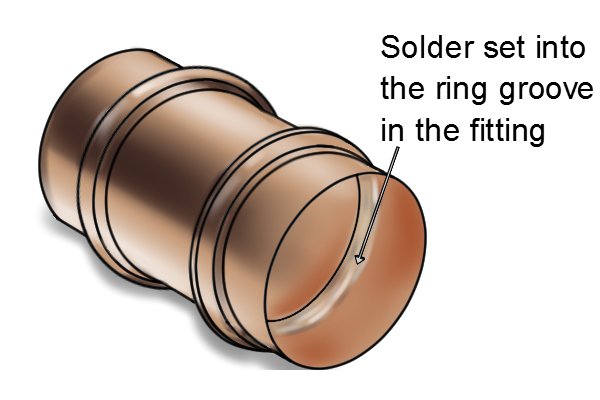

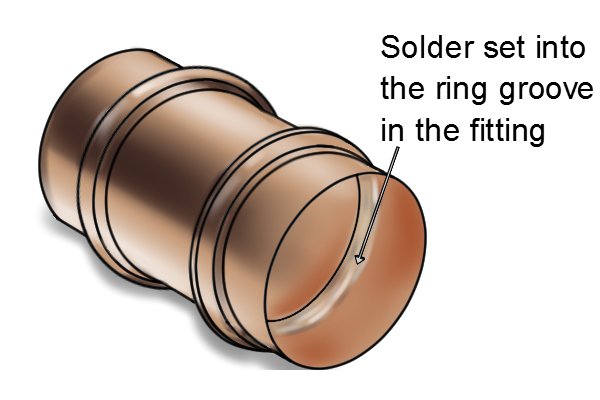

bern, when i worked at the navy yard (60's) we had to silver solder all of our joints (some were welded) . the female socket of the fittings had a groove inside and there was a ring of silver solder in the groove. similar to this.

well we were required to remove the ring, clean it with emery cloth and clean the groove as well.

then apply silver solder flux into the groove and snap the ring back into place.

department of defense (our employers) spared no expense in protecting the lives of the sailors on board the ships.

so, i know about quality control.

our work also stood two inspections.

one civilian inspector and a naval officer inspector.

one fun fact.. we never EVER used a level. "EVER" ..

oh yeah, we also scribed all our male ends of pipe with a clearly visible scratch that was exactly one inch longer than the depth of insertion.

|

|

Post Reply

|

|

|

Author:

bernabeu (SC)

packy,

does the term 'nuclear hold' ring a bell ?

to make you smile:

we had a real b*ll buster of an inspector for magnaflux inspections of welds (i was a fitter assigned to a welder)

we never could 'flat top' to meet his specs

so, with permission, i stayed several hours after quitting time one day and ground a 30" pipe joint FLUSH both externally and internally - wire wheeled the ENTIRE pipe - washed it down with Muriatic - the pri*k spent 4 hours FINDING the weld - he finally x-rayed it

aaaaaah .... the good old days .... some were actually fun

==============================================

"Measure Twice & Cut Once" - Retired U.A. Local 1 & 638

|

|

Post Reply

|

|

|

Author:

packy (MA)

bern, i did a 4 year apprenticeship at the yard.

work 3 weeks and 1 week of school every month.

i also spent 2 weeks working/observing with each trade.

electrician, shipfitter, welder, machinest, rigger, electronics, boilermaker, inspector WELL all of them.

quite a well rounded education.

|

|

Post Reply

|

|

|

Author:

sum (FL)

well, I finished hooking everything up.

This was the existing messed up valves, buried in dirt for years, all corroded PVC outside and polybutylene inside the crawlspace.

I redid the outside assembly, transitioned from PVC to copper using a FORD METER BOX IPS to CTS coupling, first time using it and no leak. Then I transitioned to copper. Total three ball valves. One for the house, then one for first floor (MAIN #1) and one for the second floor (MAIN #2).

Once I replaced the piping inside the crawlspace with PEX then line MAIN #2 will no longer be necessary so right now I am using a 3/4" flex coupling as a temp connection.

Something very strange happened. I soldered the entire assembly last Thursday, before I connected to anything. I then tested it for leaks, by using Sharkbite end caps on the open ends, and hooked up a garden hose to one of the connections, and I didn't notice any leak. Then the next day, when I cut the lines and inserted the assembly, soldered them all together, waited for it to cool off, then turned water back on, and after a while, one of the soldered joint had a very slow drip. This made no sense, because that joint wasn't leaking when I tested the assembly by itself the day before.

The only reason I could think of, was when I tested it the day before, the assembly was sealed with end caps, and when I turned the garden hose on, the entire assembly was filled with air so water cannot enter. The slow leak was not noticed because it was leaking air slowly, and it would have taken a while for all the air to be displaced before it will start leaking water to be noticed. I waited 15-20 minutes which was not long enough. When I installed the assembly into the system, and turned water on and an inside faucet on, the leak shows up almost immediately.

|

|

Post Reply

|

Please note:

- Inappropriate messages or blatant advertising will be deleted. We cannot be held responsible for bad or inadequate advice.

- Plbg.com has no control over external content that may be linked to from messages posted here. Please follow external links with caution.

- Plbg.com is strictly for the exchange of plumbing related advice and NOT to ask about pricing/costs, nor where to find a product (try Google), nor how to operate or promote a business, nor for ethics (law) and the like questions.

- Plbg.com is also not a place to ask radiant heating (try HeatingHelp.com), electrical or even general construction type questions. We are exclusively for plumbing questions.

Search for plumbing parts on our sponsor's site:

Special thanks to our sponsor:

|