Over 698,000 strictly plumbing related posts

Plumbing education, information, advice, help and suggestions are provided by some of the most experienced plumbers who wish to "give back" to society. Since 1996 we have been the best online (strictly) PLUMBING advice site. If you have questions about plumbing, toilets, sinks, faucets, drains, sewers, water filters, venting, water heating, showers, pumps, and other strictly PLUMBING related issues then you've come to the right place. Please refrain from asking or discussing legal questions, or pricing, or where to purchase products, or any business issues, or for contractor referrals, or any other questions or issues not specifically related to plumbing. Keep all posts positive and absolutely no advertising. Our site is completely free, without ads or pop-ups and we don't tract you. We absolutely do not sell your personal information. We are made possible by:

|

|

Author:

sum (FL)

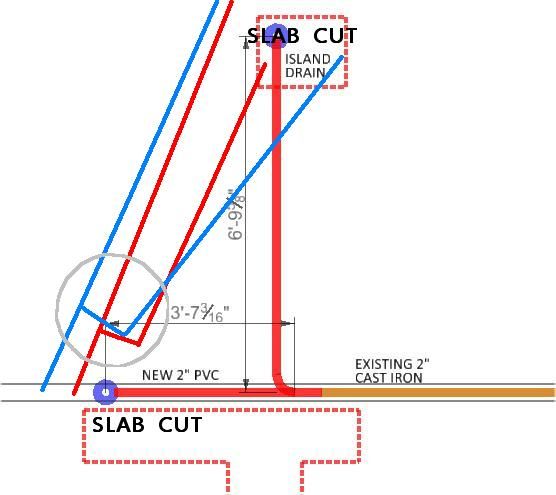

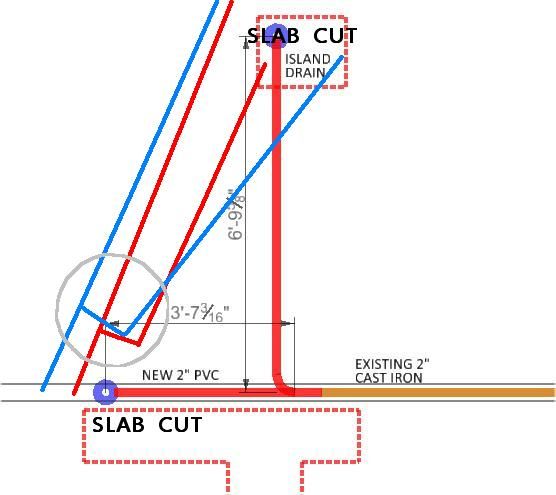

If you saw my other threads on a recent project to replace a section of 2" drain serving two apartments, you know I have the concrete slab opened up to make the plumbing changes.

What I did not expect to find is when the last owner moved the kitchen from the wall to an island, he cut the original hot and cold supply lines below grade, soldered in two tees, and ran two lines from the tees to the island location.

I found this when I excavated the drain lines. Here are some pictures showing what I have.

A closer picture.

Originally these soft copper lines have no joints underground between manifolds. Now he added a tee, then an 90 elbow to change direction towards the island, then a new pipe 7' to the island, then a 90 elbow to point up, possibly couplings in between. That's 6+ joints.

Not only that, the way he added the tee in the 3/4" cold supply line, if you look at the last up close picture, he used a 1/2" tee, so the line went from 3/4" to 1/2" back to 3/4" through the tee.

Here is a sketch of what he did. On the lower left is where he put in the tees.

I am debating whether I should leave it alone or try to fix it best I can.

On one hand, the renovation was done in 2008, and these soldered joints have not leaked. Most likely they will be OK for years to come. Furthermore, I can't think of a way to completely eliminate all the joints, I can possibly reduce it, but not totally. Finally, access is difficult as these joints are actually under the slab and about 16" from the edge of the slab. I can't cut more slab because the other side of the wall are existing kitchen cabinets with granite countertop and tiled backsplash. I can't imagine how I would solder in such a tough spot.

On the other hand, if I am going to do anything at all, now is the time when I have no kitchen cabinet on this side, and the slab opened up.

What would you recommend? Leave it alone and move on or bite the bullet and try to remedy this best I can?

Edited 3 times.

|

|

Post Reply

|

|

|

Author:

sum (FL)

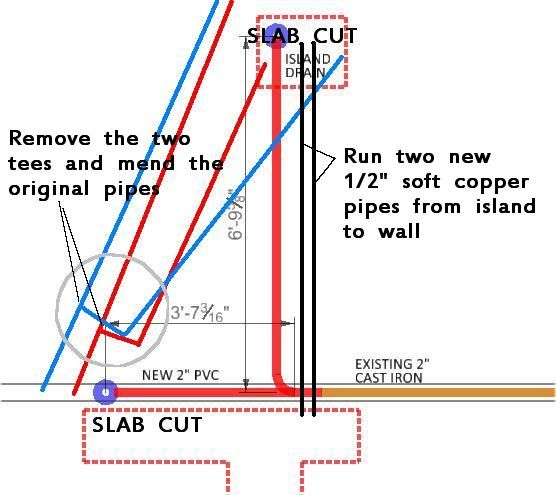

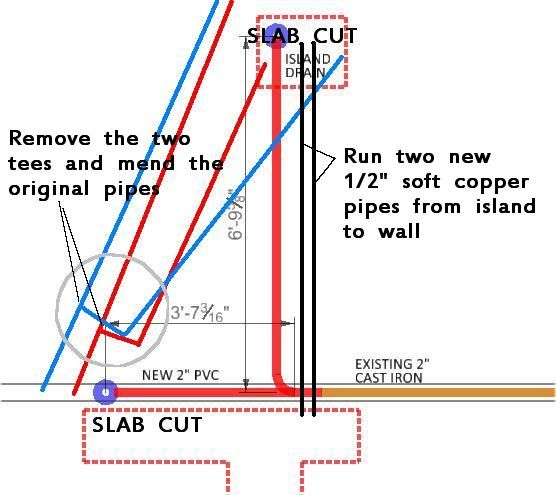

Been thinking about this problem all day. Here is what I am contemplating.

I know I can run new 1/2" pipes from that wall to the island. I can do the same as I did with the 2" drain and punch a hole through to fit two 1/2" soft copper pipes. It would be much easier than the 2" drain, and if I do it near the drain some of the sandy soil is already loose it wouldn't be much effort at all and I don't need to keep any sort of pitch. The pipes would be bent at both ends so there is no underground joints. I can tie the pipes back to the manifold by a few soldered joints inside the wall cavity.

If I do that then the two tees off the original pipes are no longer needed. I can cut the tees out with a tubing cutter. That would leave me with two "broken" pipes, one 3/4" and one 1/2" with a gap in between. I don't think I can solder in that tight space, so that boils down to two questions.

(1) What is the best way to mend the 3/4" and 1/2" after the tees are cut out, that is suitable for underground and buried, if I can't solder or braze? Would a potable water rated long compression coupling work here? Would a dresser coupling for copper pipes work here?

(2) Whatever method to use for question #1, is that method going to result in a stronger joint then the existing soldered joints that have held for 8 years? If the answer is no, then I will leave all this alone.

|

|

Post Reply

|

Please note:

- Inappropriate messages or blatant advertising will be deleted. We cannot be held responsible for bad or inadequate advice.

- Plbg.com has no control over external content that may be linked to from messages posted here. Please follow external links with caution.

- Plbg.com is strictly for the exchange of plumbing related advice and NOT to ask about pricing/costs, nor where to find a product (try Google), nor how to operate or promote a business, nor for ethics (law) and the like questions.

- Plbg.com is also not a place to ask radiant heating (try HeatingHelp.com), electrical or even general construction type questions. We are exclusively for plumbing questions.

Search for plumbing parts on our sponsor's site:

Special thanks to our sponsor:

|