Over 698,000 strictly plumbing related posts

Plumbing education, information, advice, help and suggestions are provided by some of the most experienced plumbers who wish to "give back" to society. Since 1996 we have been the best online (strictly) PLUMBING advice site. If you have questions about plumbing, toilets, sinks, faucets, drains, sewers, water filters, venting, water heating, showers, pumps, and other strictly PLUMBING related issues then you've come to the right place. Please refrain from asking or discussing legal questions, or pricing, or where to purchase products, or any business issues, or for contractor referrals, or any other questions or issues not specifically related to plumbing. Keep all posts positive and absolutely no advertising. Our site is completely free, without ads or pop-ups and we don't tract you. We absolutely do not sell your personal information. We are made possible by:

|

|

Author:

sum (FL)

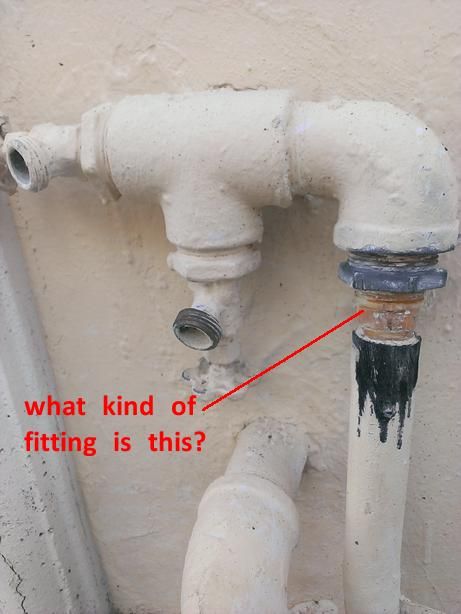

Now that I got my pump working I would like to redo the outflow line contraption that consists of galvanized metal, PVC, and some plastic hose.

The line to the right side coming out of the wall is a galvanized tee 1.5". I want to transition that to 1" with a bushing, then go down and out with PVC.

I am thinking they used a hose because the elbow threaded into the tee doesn't point straight down, and the hose let them bend it a little.

I am sure I can special order some 11 degree pressure fitting but short of doing that, is there any trick if I use a straight piece down, then I need to make a 100 degree elbow. Can I use two 45 elbows and roll them this way and that to get me a larger than 90 degree turn?

|

|

Post Reply

|

|

|

Author:

North Carolina Plumber (NC)

You could heat the pipe and bend it to the desired angle.

|

|

Post Reply

|

|

|

Author:

steve (CA)

How about turning the st 90*, so it's pointing 45* from vertical and then use a 45* to go straight down? The intake piping is already sticking out from the wall, so this won't be sticking out any farther.

|

|

Post Reply

|

|

|

Author:

sum (FL)

N C Plumber, I have seen this done on some video, if I remember it requires hot sand to be poured into the pipe right? I don't think I have the skills for this.

|

|

Post Reply

|

|

|

Author:

sum (FL)

Steve, I will try that tomorrow, although I don't know the condition of the threads and how corroded the galvanized metal is. I don't want to brute force it and break the 1953 antique elbow.

If nothing works I can use two 90s swing one against the wall and roll the other one horizontal I just need to chip more concrete away.

|

|

Post Reply

|

|

|

Author:

Paul48 (CT)

I missed it....How did you get it working sum?

|

|

Post Reply

|

|

|

Author:

sum (FL)

Paul, the pump was fine, air was being let in somewhere. I was bouncing against every wall last weekend.

Read my last post in this thread.

[www.plbg.com]

|

|

Post Reply

|

|

|

Author:

sum (FL)

I tried unthreading that metal bushing, with a 18" plumbers wrench, the biggest u have, did not move any. Cleaned up the paint, tried again, same result.

Should I take a 4' steel pipe to leverage the wrench or would I break it?

|

|

Post Reply

|

|

|

Author:

North Carolina Plumber (NC)

I would leave it be, if you're careful you can heat and bend the pipe without sand in it, just use a heat gun or possibly a hair dryer. You can practice on a scrap piece.

|

|

Post Reply

|

|

|

Author:

hj (AZ)

The 11 degree fitting would not only have to be special ordered, they would have to manufactured, after you paid ALL the tooling costs and the injection molds.

|

|

Post Reply

|

|

|

Author:

sum (FL)

Update: I got it to unthread after putting a 4' long galanized pipe over the handle of my wrench. It was on real tight. I had to use that pipe to turn a good two full revolutions before I can use just the wrench to turn it.

Thank you Archimedes who I believe is responsible for the lever principles. That comes in handy.

Now on to getting the plumbing line finished.

|

|

Post Reply

|

|

|

Author:

sum (FL)

I used two 45 elbows and rolled them this way and that until I got one end to point straight down. Smooth sailing from here on out.

|

|

Post Reply

|

|

|

Author:

PlumerDan (CA)

sum...why did you reduce your riser/ you have one inch comminig over and one inch looking down...just courious...dan

|

|

Post Reply

|

|

|

Author:

sum (FL)

Dan, that is because the outflow line is all 1" line, and the 1.5" section you see in the picture is only about 24" long then it's 1" all the way. Whoever put this together before me used a mix of 1.5", 1.25", 1" in sizes of PVC, plastic hose, galvanized iron all of these in the first 30" of the line.

|

|

Post Reply

|

|

|

Author:

North Carolina Plumber (NC)

That hose is actually Polyethylene, or black roll pipe. They used a nylon insert male adapter to transition to it. That's what we use to hang deep well pumps on down to 500' or so.

|

|

Post Reply

|

|

|

Author:

greekguy7 (IL)

Good job breaking that old fitting loose! Did you use a second wrench to hold back on while using the 4' long galvanized pipe over the handle of your pipe wrench?? With my luck, I would have broken something else loose instead.

|

|

Post Reply

|

|

|

Author:

sum (FL)

NC Plumber, how did they connect the Polyethylene pipe to the male adapter. As far as I can tell, it is not threaded, there is no hose clamp, so they are just held together by friction?

|

|

Post Reply

|

|

|

Author:

sum (FL)

greekguy7, I did not use a second wrench to kept the elbow in place. I was really turning it slow, with control. I figured if the elbow breaks then it's time to replace the elbow anyways.

|

|

Post Reply

|

|

|

Author:

sum (FL)

Well the bobcat rolled over the in take pipe and broke the PVC portion today.

Might as well as I didn't like the three 90 elbows. So I used the wrench and long iron pipe and removed metal 1.5" nipple from the intake side.

|

|

Post Reply

|

Please note:

- Inappropriate messages or blatant advertising will be deleted. We cannot be held responsible for bad or inadequate advice.

- Plbg.com has no control over external content that may be linked to from messages posted here. Please follow external links with caution.

- Plbg.com is strictly for the exchange of plumbing related advice and NOT to ask about pricing/costs, nor where to find a product (try Google), nor how to operate or promote a business, nor for ethics (law) and the like questions.

- Plbg.com is also not a place to ask radiant heating (try HeatingHelp.com), electrical or even general construction type questions. We are exclusively for plumbing questions.

Search for plumbing parts on our sponsor's site:

Special thanks to our sponsor:

|